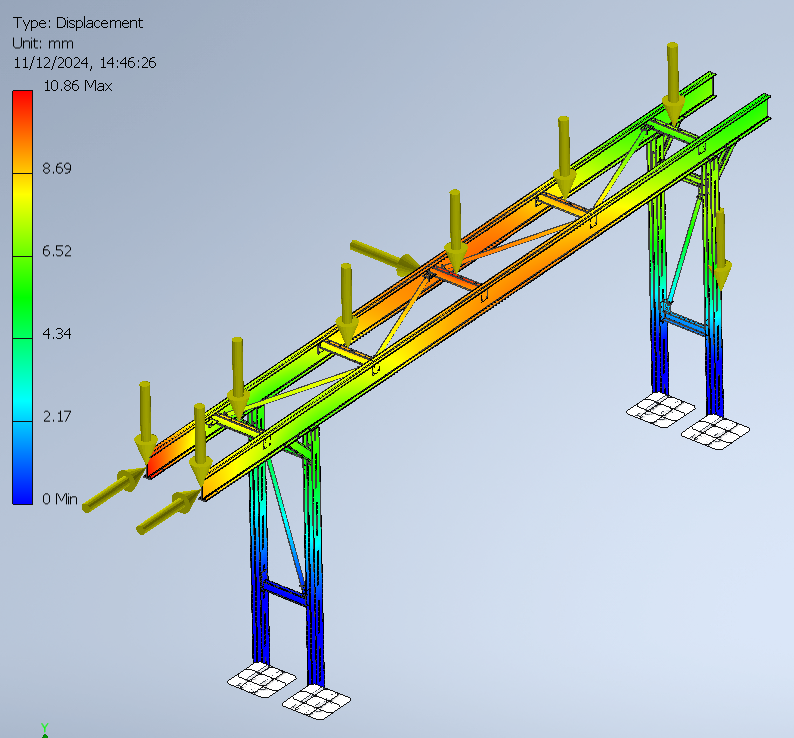

At Allied Protek, innovation drives our approach to engineering, and one of the key tools propelling us forward is Finite Element Analysis (FEA). By integrating advanced FEA software into our design process, we’re taking structural analysis and optimisation to unprecedented levels of precision and reliability, allowing us to identify problem areas at the earliest stages.

What is Finite Element Analysis?

Finite Element Analysis (FEA) is a computational method which allows our design engineering team here at Allied Protek to simulate and predict how structures, components, and vessels will respond to various loading scenarios.

These include forces, gravity, and pressure, which are crucial factors in assessing performance. With this software, we can observe stress distribution, deflection, and other critical responses at a granular level, providing invaluable insights into the behaviour of complex assemblies.

Benefits of FEA in Our Design Process

Identifying Issues Early: By simulating real-world loading conditions in fine detail, we can predict and address potential issues before fabrication begins. This early detection saves time and resources, ensuring that designs meet performance expectations.

Accuracy and Confidence: The simulations that we generate provide highly accurate data on stress distribution, deflections, and loads. This allows our team to design with confidence, maintaining required safety factors and adhering to relevant design codes such as Eurocode 3.

Streamlining Complex Designs: Advanced FEA software accelerates the design process, enabling us to tackle those more intricate projects with more efficiency, without compromising on quality or safety.

Comprehensive Load Analysis: We can precisely determine the impact of imposed loads on adjoining structures and fixings, including critical components such as hold-down bolts. This ensures a robust and reliable assembly in every project.

Why It Sets Allied Protek Apart

While FEA is widely recognised as a sophisticated engineering tool, it is rarely adopted outside high-tech industries. At Allied Protek, our ability to use FEA gives us a significant competitive edge. It allows us to bring the same level of engineering rigour, typically reserved for aerospace and automotive applications to industrial, manufacturing, and process engineering projects. This capability positions us as leaders in the field, offering advanced solutions that few competitors can match.

Real-World Applications

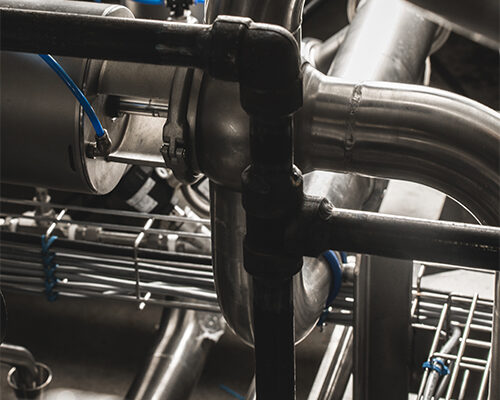

Our use of FEA spans a wide array of applications. Whether it’s analysing the structural integrity of a custom-built vessel or ensuring the reliability of a critical assembly under extreme conditions, Allied Protek will deliver precision-engineered solutions tailored to meet your specific requirements.

The result? A safer, more efficient, and more cost-effective design that exceeds expectations.

PARTNERING WITH ALLIED PROTEK

Choosing Allied Protek means gaining access to top-tier engineering expertise and the tools that ensure that your project is built to last. Our commitment to innovation and excellence drives us to leverage advanced technologies like FEA to deliver unmatched results for our clients.

Discover how Allied Protek’s expertise in Finite Element Analysis can elevate your next project. Contact our team today!

Recent Projects